Energy Storage Systems: the role of an Integrator

Simplifying BESS deployments by mastering their associated risks

With the introduction of Battery Energy Storage Systems ‘BESS’, a new role has been created on the value chain. It is the role of a BESS integrator.

The role of an integrator can be misunderstood at times or blended with other roles at other times. This is why we are trying here to highlight the role of a BESS integrator and how it is different from other roles and what to look for when selecting an integrator partner for your storage projects.

Let’s start with having a helicopter view at how connecting a BESS system may look like. Although it may seem simple at the first glance to connect the Battery Racks, Power Conversion Systems, Transformers, and the Software and Controls together (see fig. 1), it is more complex than that.

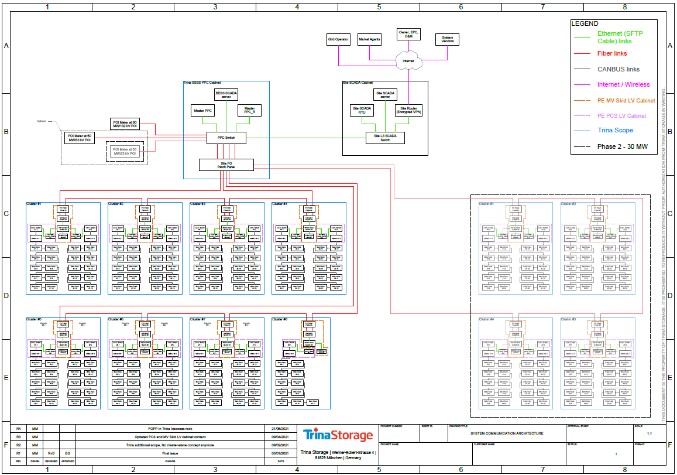

Let us work with an assumption and take the below SLD as an example. This project will have a size of “50MW|1h”, will be requested to provide grid-support services “FFR, DC, BM, Wholesale arbitrage” so the battery will have to undertake an average of 2 cycles/day with up to 4 cycles/day to reap in more revenues. The system performance and safety will have to monitor and control in real-time. And the client requested system performance, as well as system availability, is to be covered by a 10-year warranty and long-term service agreement. That is an example of how complex it can get for an integrator to ensure the delivery of a bulletproof design, future-proof performance, and cost-competitive solution comprising of hardware, software, and a full wrap of warranties.

What is the role of an integrator?

The simple answer is “its main role is putting all pieces of the puzzle together”, but the long one is… multi-dimensional role comprising of the following objectives:

A. Design for success

With so many players with different backgrounds (e.g. electrical contractors, solar EPCs, battery or inverter manufacturers or software providers) penetrating the energy storage space it is paramount that the integrator provider you are going to select for your storage project will be able to (1) thoroughly understand and analyze the specific project requirements and the impact of the requested load profile on battery degradation, performance, availability, and safety; (2) recommend and interact with the Client to reach the sweet spot and (3) Design the ideal battery configuration to maximize ROI.

The design phase entails several aspects. Electrical is the most obvious, but there are many others: mechanical, safety, standards and compliance, scheduling, etc. Take communications as an example: every piece of equipment needs to communicate correctly with its peers and with other equipment on site. You need to assure that the battery modules are communicating inside the same battery rack; that each rack is coordinated with other racks connected to the same DC busbar; that the PCS have the appropriate set points; that the EMS is correctly communicating the inputs to the PPC and so on.

Just looking at the number of abbreviations regarding the control of a BESS, we can feel the level of complexity this implies and the number of devices that must be

synchronized together: EMS, PPC, BMS, MBMU, PMS, SCADA…

B. Deliver with minimum supply & installation risks

Now that Electric Vehicles make more than 65% (Wood Makenzie) and will continue to make the lion’s share of the global lithium-ion battery demand, battery OEMs will often prioritize orders from EV manufacturers. Wood Mackenzie stated in a recent report that “Pricing and product availability will remain, key differentiators when selecting battery technology for energy storage applications”. To bring down this supply risk to a minimum, many BESS project developers are approaching the market on a partnership model with BESS integrators with strong, stable, and diversified supply chain networks.

This phase kicks off once the final design of the BESS is decided and the contract has been signed. Then, the supply of the equipment starts with all the logistics behind. This phase entails the management of the logistics of the different equipment up to the site, including along the way the respective FAT to be performed.

One key aspect in this phase is to be able to assure that the timelines are met. Most likely the battery racks or the MV equipment will represent the lengthiest equipment to arrive on site. Therefore, making sure that the volumes and supply chain is warranted is key.

The commissioning of the entire system on-site warrants the proper functioning of the BESS as a whole making sure that what was designed is delivered, i.e. making sure that the power, the capacity, the RTE, the reaction time… is in line with the expectations.

C. Ensure a lifetime performance

So, you have been able to secure (i) a bullet-proof design, (ii) a good “CAPEX” price, and (iii) the needed volumes and timelines for your storage projects. Now it is time to address – the yet mysterious side for many – the long-term performance commitments.

Due to battery and components degradation, the system performance changes along the project lifetime, and the integrator should accompany the Client over the entire project lifetime. This implies committing themselves in the long-term to assure that (i) the BESS is well maintained and that (ii) the warranties are respected.

As a BESS asset developer/investor, Product and Performance Warranties are key to de-risk the investment and increasing the bankability of the storage assets. One should always consider this second half of the cost equation “how much will it cost to warrant the overall system performance over the project lifetime?” & “how much will it cost to warrant against flexible cycling profiles if needed*?”. One should not be tempted to go for a relatively cheaper solution at year 0, and always consider the project lifecycle costs.

In conclusion…

The key role of an integrator is to optimize to maximize profits while ensuring reliable and safe delivery and operation.

- The integrator should have the expertise and capabilities to optimize and deliver A competitive solution according to your needs.

- The integrator should have strong supply chain networks and strategies to cater for your immediate and future storage plans and to internalize any externality.

- The integrator should have the financial capability to back-up the solution and accompany you in the long run.

By Ramy Shahat and Juan Ceballos, Trina Storage

———————————————————————-

About Trina Storage

Trina Storage, business unit of Trina Solar, is a global energy storage system

provider dedicated to transforming the way we provide energy. Our mission is to lead the

renewable energy transition through cost-effective storage and to provide Solar For

Everyone by expanding solar generation at scale. Building on 20+ years of solar experience,

we deliver cost-effective and flexible solutions to utilities and developers around the world.

More information at Trina Storage website.

About Trina Solar

Over 20 years Trina Solar has been evolving from a top class PV module supplier to the

world’s leading PV and smart energy total solutions provider, with PV products, system

solutions and smart energy. The company manufactures, sells and does research and

development on PV products, EPC and O&M as well as smart micro-grid and multi-energy

complementary systems and energy cloud-platform operations. Trina Solar has a presence

in more than 100 countries and regions, including regional headquarters in Zurich, San Jose,

Miami, Tokyo, Singapore, Dubai. The company operates eight manufacturing bases and

more than 40 branches and has more than 12,000 employees worldwide.

If you want to know more about this and other topics directly from end users of energy storage technologies join us at one of these annual events: The Energy Storage World Forum (Grid Scale Applications), or The Residential Energy Storage Forum, or one of our Training Courses.